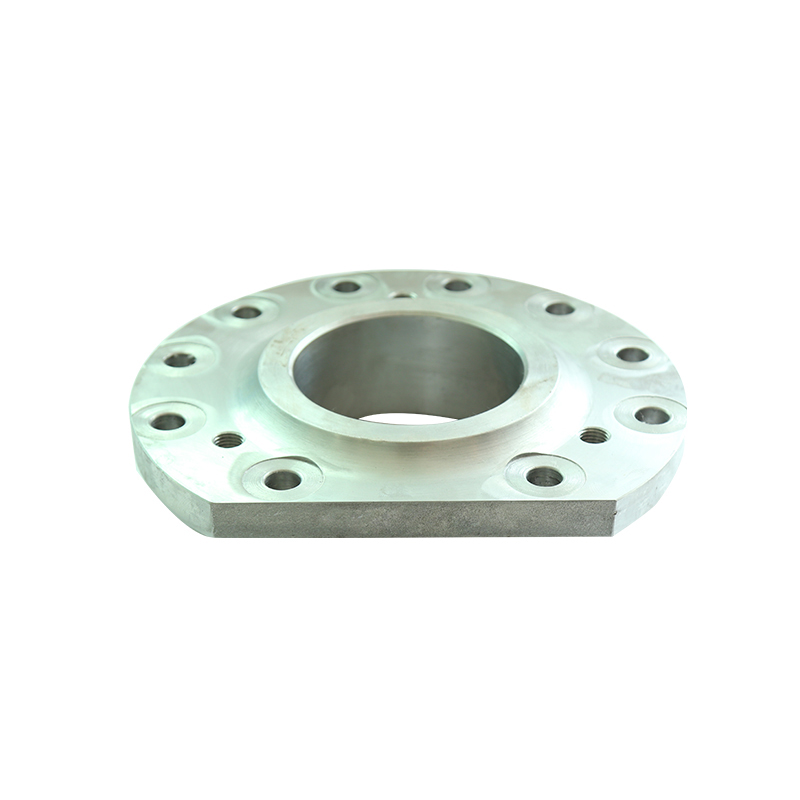

Introduction of casting wheel hub:

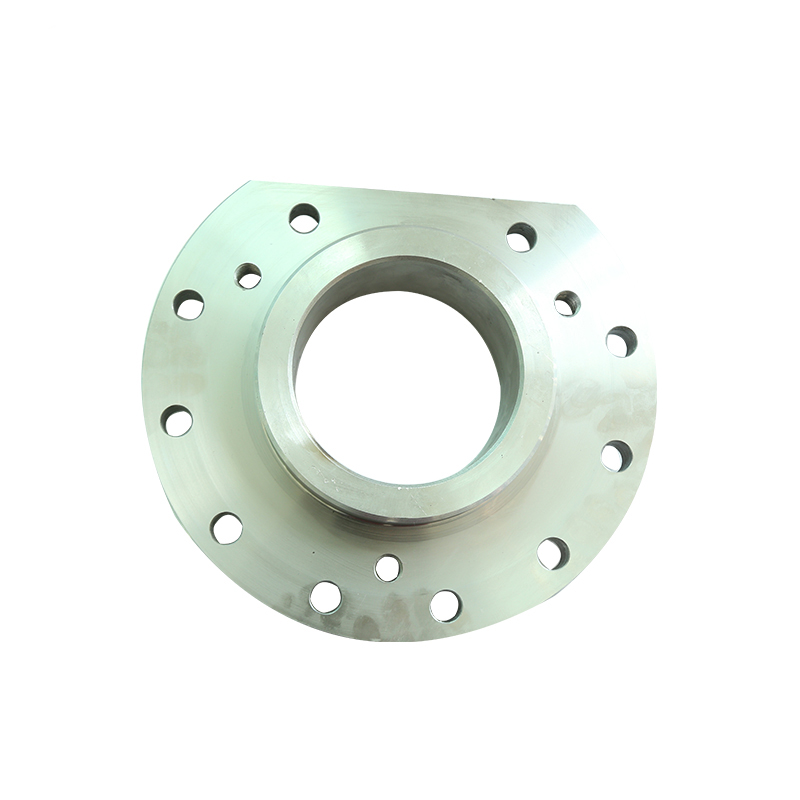

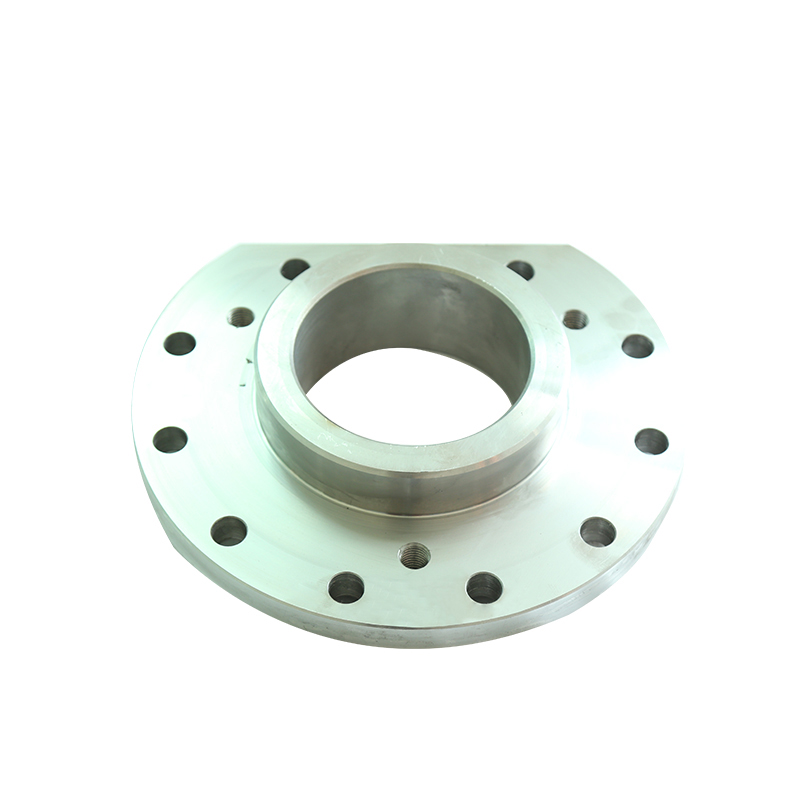

Casting wheel hub is made by silica sol process and lost wax method. The advantage of this casting is that it can accurately measure and produce surface quality. Casting wheel hub is widely used in mechanical equipment, automotive parts, industrial equipment and other fields, and has corrosion resistance. The surface of casting wheel hub is sandblasted, which can effectively remove burrs, cracks, oxide scale and other uneven parts on the surface of casting wheel hub, so as to obtain a smoother surface structure.

Advantages of the process:

1. Tensile strength ≥ 520 MPa, closer to forgings, yield strength ≥ 205 MPa, improved durability and deformation resistance.

2. Density 7.85 g/cm³, close to forgings, almost no pores and inclusions, reducing casting defects and improving reliability.

3. Material utilization rate reaches 95-98%, much higher than sand casting, less material waste, and improved production economy.

Processing and production process:

1. Drawing confirmation: Analyze and confirm production according to the drawings provided by the customer.

2. Mold making: Use advanced mold manufacturing technology to ensure the dimensional accuracy of casting stainless steel wheel hub, with a tolerance of ±0.01mm - 0.1mm.

3. Lost wax casting: High temperature melting wax mold, casting stainless steel wheel hub molding consistency is guaranteed.

4. Precision casting: The silica sol process is used to improve the surface quality and strength of casting stainless steel wheel hub, with fewer pores and slag inclusions.

5. Heat treatment and surface treatment: Sandblasting process improves appearance.

6. Quality inspection: Strictly inspect in accordance with ISO quality system.

7. Packaging and transportation: Casting stainless steel wheel hub adopts protective packaging, using iron boxes and wooden boxes, and can also be packaged according to your needs.

Technical parameters of casting wheel hub:

| Material | Ductile cast iron, grey cast iron, steel |

| Sand of casting wheel hub | Green sand, Clay sand, resin sand |

| Process stainless steel wheel hub for auto | Sand casting, Shell core casting |

| Machine | Lathe, CNC machine, turning machine, drilling machine, millingmachine, boring machine, machining center |

| Casting Tolerance Min | 0.05mm |

| Machining Tolerance Min | 0.02mm |

| Surface Treatment | Painting,Powder coating,spraying, galvanization, chrome plating |

| Unit Weight | 0.5kg~500kg |

| Application | Auto parts, kitchen parts, mining machine parts, railway parts,construction parts, so forth |

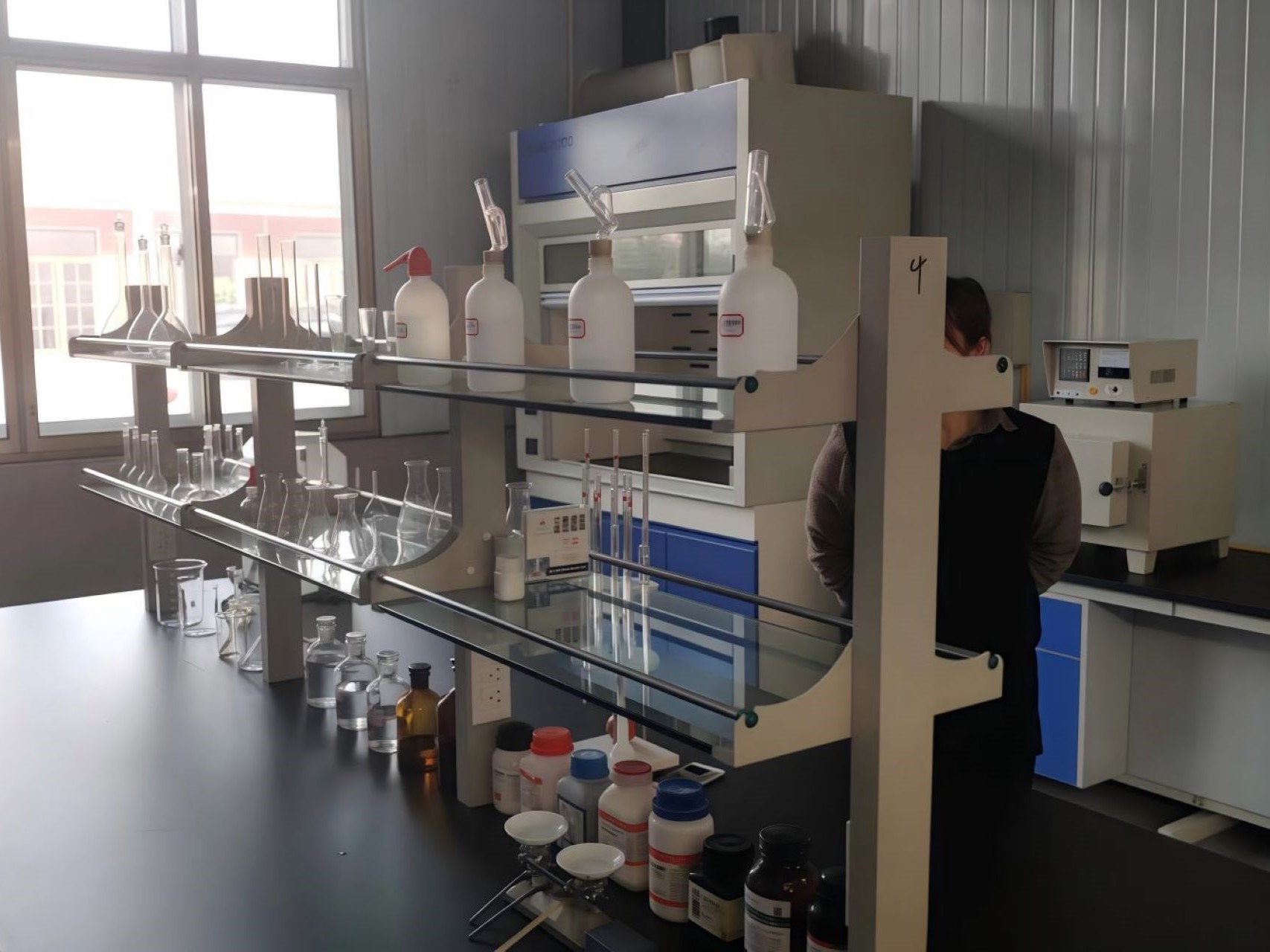

| Test Equipment | CMM,spectrometer,tensile tester, hardness tester, chromethickness tester,Metallographic tester, so forth |

| Standard | ISO,ASTM.JIS, ANSI. DIN, BS.GB |

| Certification | ISO9001:2008 |

| Service | OEM & ODM |

About us:

With our high precision manual mechanical measuring tools we are able to achieve 100% dimensional control, ensuring every part meets exacting standards. We use 3D scanning technology and state-of-the-art three-axis measuring machines for quality checks. Our goal is to provide you with quality products, trust us, you will be impressed by our quality and precision.