Introduction of stainless steel casting auto parts:

Stainless steel casting auto parts adopts silica sol casting. Silica sol casting is a kind of investment casting process. Also known as investment casting, it is a precision casting process widely used in industrial manufacturing. Stainless steel casting auto parts adopts 304 and 316 stainless steel, and the surface of stainless steel casting auto parts is smooth through sandblasting surface treatment.

Advantages of casting auto parts:

1. Casting auto parts uses wooden boxes or iron boxes for transportation and packaging, or according to your needs to avoid damage.

2. Casting auto parts is strictly controlled from mold design to casting molding to ensure the highest quality.

3. Casting auto parts uses surface treatment methods such as sandblasting to make the casting surface more beautiful and durable.

Technical parameters of stainless steel cast auto parts:

| Material | Ductile cast iron, grey cast iron, steel |

| Sand | Green sand, Clay sand, resin sand |

| Process | Sand casting, Shell core casting |

| Machine | Lathe, CNC machine, turning machine, drilling machine, millingmachine, boring machine, machining center |

| Casting Tolerance Min | 0.05mm |

| Machining Tolerance Min | 0.02mm |

| Surface Treatment | Painting,Powder coating,spraying, galvanization, chrome plating |

| Unit Weight | 0.5kg~500kg |

| Application | Auto parts, kitchen parts, mining machine parts, railway parts,construction parts, so forth |

| Test Equipment | CMM,spectrometer,tensile tester, hardness tester, chromethickness tester,Metallographic tester, so forth |

| Standard | ISO,ASTM.JIS, ANSI. DIN, BS.GB |

| Certification | ISO9001:2008 |

| Service | OEM & ODM |

FAQ:

Q1: What are the main differences between silica sol investment casting and water glass casting?

A1: Silica sol casting provides better surface quality and precision. Although it is more expensive, it is very suitable for applications that require high-precision and corrosion-resistant parts. The water glass casting method is less expensive, but the surface is rough and the precision is poor.

Q2: Can you provide customized services?

A2: Yes, we provide a full range of customized services, and you can customize the specifications and surface treatment methods according to your needs.

About us:

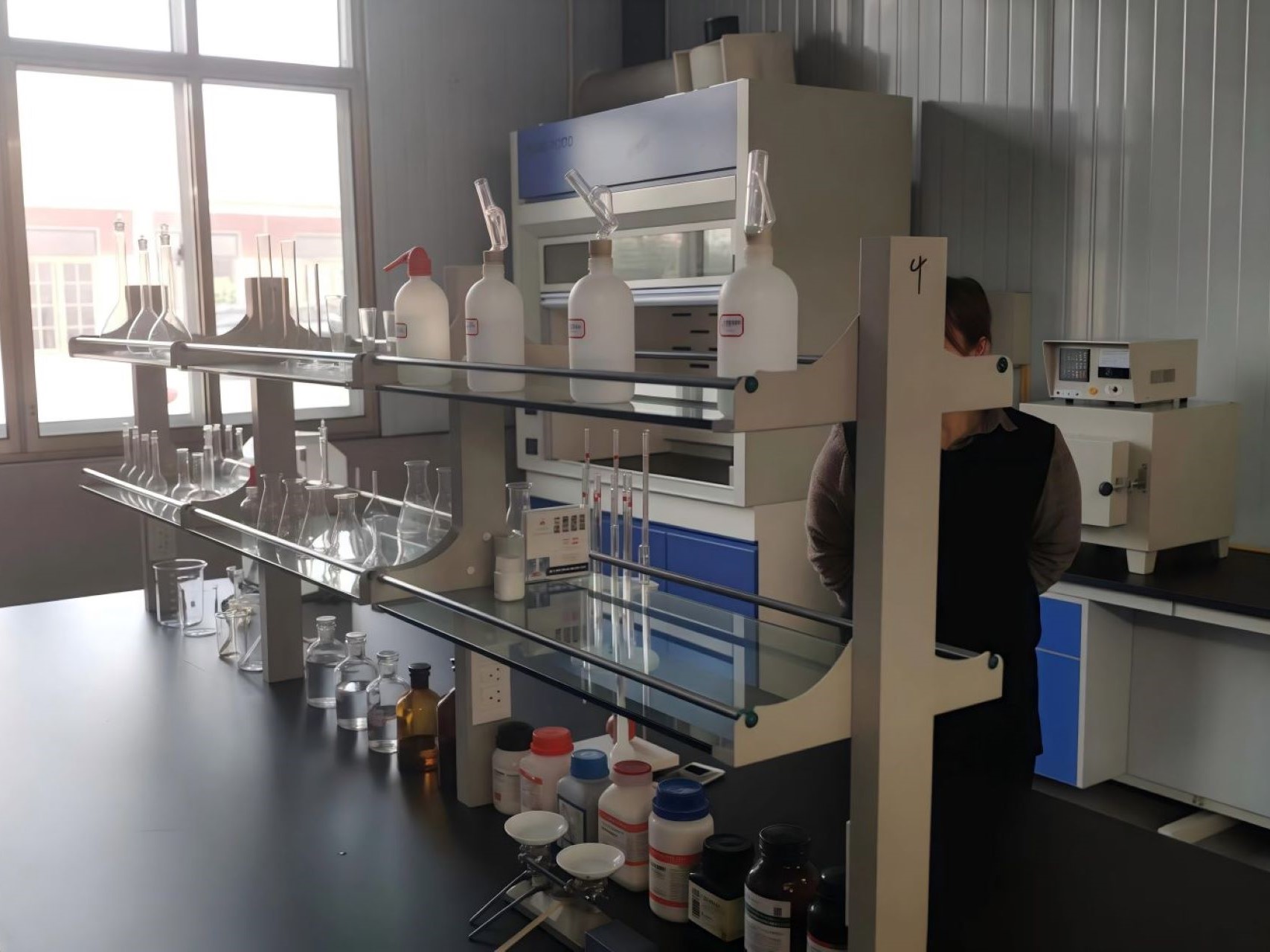

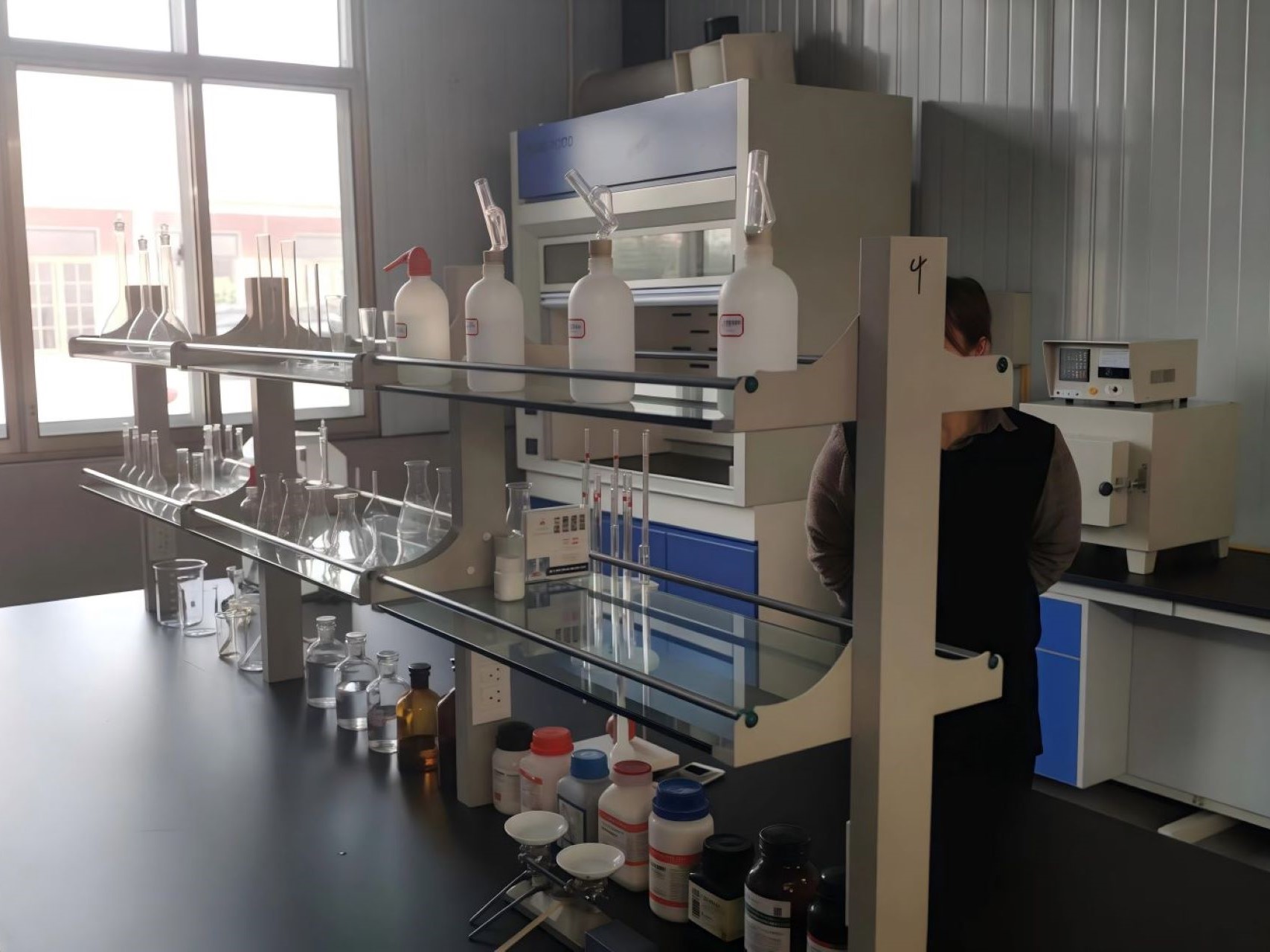

With our high precision manual mechanical measuring tools we are able to achieve 100% dimensional control, ensuring every part meets exacting standards. We use 3D scanning technology and state-of-the-art three-axis measuring machines for quality checks. Our goal is to provide you with quality products, trust us, you will be impressed by our quality and precision.