Introduction of conveyor chain sprocket for agricultural machinery:

Conveyor chain sprocket for agricultural machinery is a mechanical component used to transmit power and rotational motion, and is widely used in various transmission systems, such as crawler vehicles, industrial conveying equipment, etc. Compared with gears, conveyor chain sprocket for agricultural machinery is more suitable for transmission occasions with a larger wheelbase, and can effectively reduce friction loss and improve power transmission efficiency.

Advantages of conveyor chain sprocket:

1. conveyor chain sprocket can directly match the world's mainstream brand sprockets, easy to install.

2. From light conveying equipment to heavy industrial machinery, sprocket for agricultural machinery can stably transmit power and reduce equipment maintenance costs.

3. Sprocket for agricultural machinery adopts CNC precision machining and heat treatment technology. The size of sprocket for agricultural machinery is more accurate, the hardness is more uniform, and the operation is smoother.

Technical parameters of conveyor chain sprocket:

| Material | Ductile cast iron, grey cast iron, steel |

| Sand | Green sand, Clay sand, resin sand |

| Process | Sand casting, Shell core casting |

| Machine | Lathe, CNC machine, turning machine, drilling machine, millingmachine, boring machine, machining center |

| Casting Tolerance Min | 0.05mm |

| Machining Tolerance Min | 0.02mm |

| Surface Treatment | Painting,Powder coating,spraying, galvanization, chrome plating |

| Unit Weight | 0.5kg~500kg |

| Application | Auto parts, kitchen parts, mining machine parts, railway parts,construction parts, so forth |

| Test Equipment | CMM,spectrometer,tensile tester, hardness tester, chromethickness tester,Metallographic tester, so forth |

| Standard | ISO,ASTM.JIS, ANSI. DIN, BS.GB |

| Certification | ISO9001:2008 |

| Service | OEM & ODM |

FAQ:

Q1: How to choose the right sprocket model?

A: Please choose the right sprocket according to your chain specifications, application environment, load requirements and transmission accuracy.

Q2: What are the surface treatment methods for sprockets?

A: We provide a variety of surface treatments such as galvanizing, nickel plating, quenching hardening, phosphating, etc. to enhance corrosion resistance and wear resistance.

Q3: Can your sprockets be customized?

A: Yes! We accept customization according to customer drawings or samples, and support non-standard requirements such as various apertures, number of teeth, thickness, material, etc.

About us:

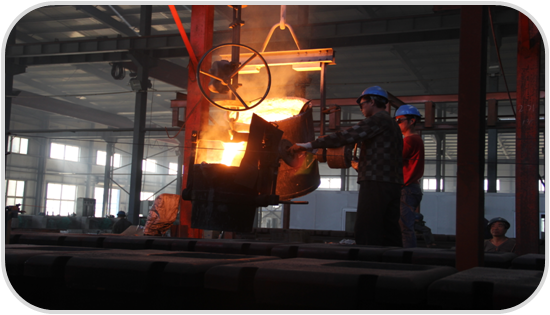

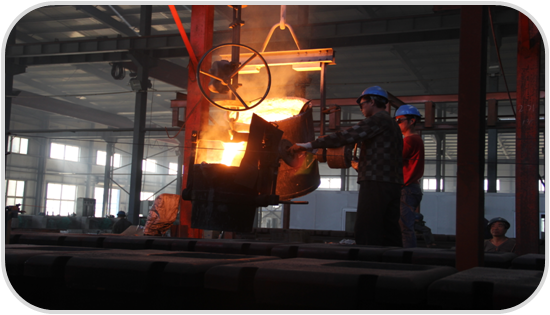

This product is sand cast, a process we specialize in and a very adaptable one. It is ideal for making simple to very complex metal parts. Because of this flexibility, we can make custom sand cast parts in a variety of shapes and sizes, and in a variety of metal alloys, whatever your production volume. We also inspect our products using 3D scanning and advanced three-axis measuring machines.