Introduction of cast iron gear casting:

Cast iron gear casting is a key component in mechanical transmission systems and is widely used in various industrial equipment. We mainly have the following two types of cast iron gear casting.

1. Gray cast iron gear:

Features: Gray cast iron contains graphite, which can play a lubricating role in the work of transmission gear and reduce friction.

Application: It is often used in transmission gear system structures with small load-bearing capacity, low transmission speed, low impact resistance but compact design.

2. Ductile iron gear:

Features: Ductile iron has excellent comprehensive mechanical properties, good process performance, and is relatively cheap. It is a high-quality material for manufacturing transmission gear.

Application: It is suitable for closed transmission systems and is widely used in automobiles, tractors, agricultural machinery, machine tools and other industries. For example, spiral bevel gears in automobile rear axles and tractor gearbox gears.

Advantages of transmission gear:

1. We can produce and process cast iron gear casting according to the drawings you provide, and the color and size can be customized.

2. The main raw materials of sand casting are casting sand and binder, which are low-cost and easy to manufacture. Therefore, the price of transmission gear cast by sand casting is more suitable than gears made by other processes.

3. Sand casting is divided into clay, organic binder, lost foam, etc., which can make the size of transmission gear more precise.

Cast iron gear casting production process:

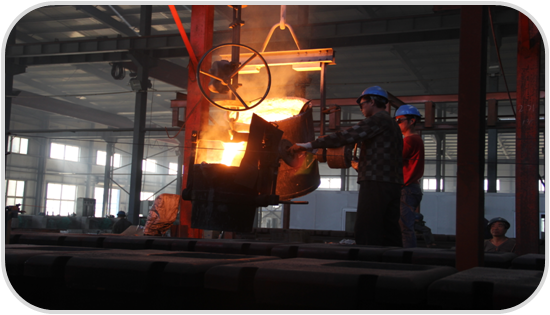

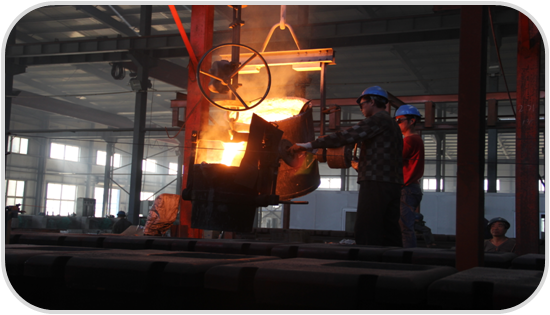

Cast iron gear casting uses sand casting, which is a common casting process, mainly including the following steps:

1. Mold making: Design and make sand molds according to the size, shape and working conditions of cast iron gear casting. We usually use materials such as quartz sand or perlite sand, and can also replace other materials according to your needs.

2. Sand core making: Make sand cores to form the internal cavity of transmission gear. Natural or artificial graphite sand cores are often used to make the shape correct and the surface smooth.

3. Melting and casting: Send the sand mold and sand core into the furnace, control the melting and casting temperature, pressure and pouring speed, and cool after the casting is completed.

4. Cooling: Control the cooling temperature to avoid quality problems such as thermal cracks or inclusions.

5. Deburring: Treat the surface of the casting by shot blasting or chemical cleaning to make the transmission gear smooth and flat.

About us:

Hengrui is equipped with advanced laboratories that can accurately detect the chemical and mechanical properties of each melt and conduct in-depth analysis of the metallurgical condition of the molten metal before pouring. In addition, we use microscopic section inspection technology to conduct detailed analysis of materials under a microscope. With strict quality control, advanced testing equipment and a professional technical team, our goal has always been to provide customers with high-quality casting products and help customers achieve excellent engineering applications.