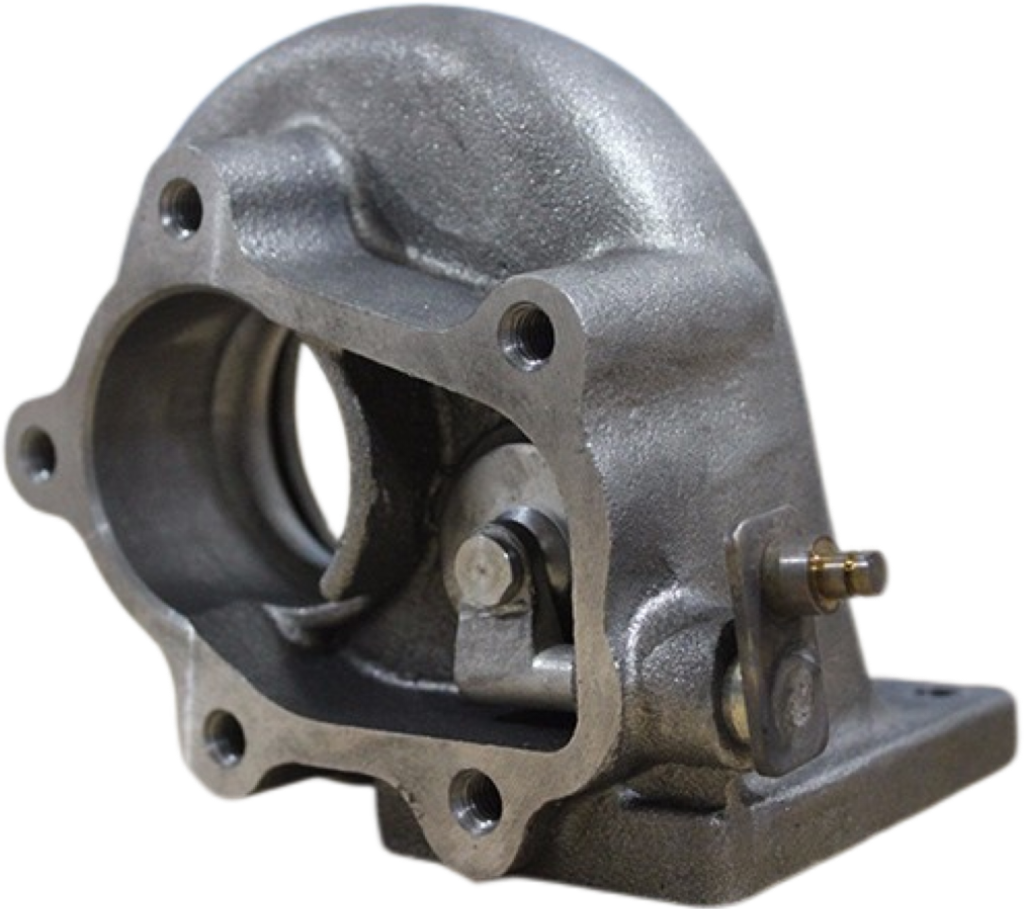

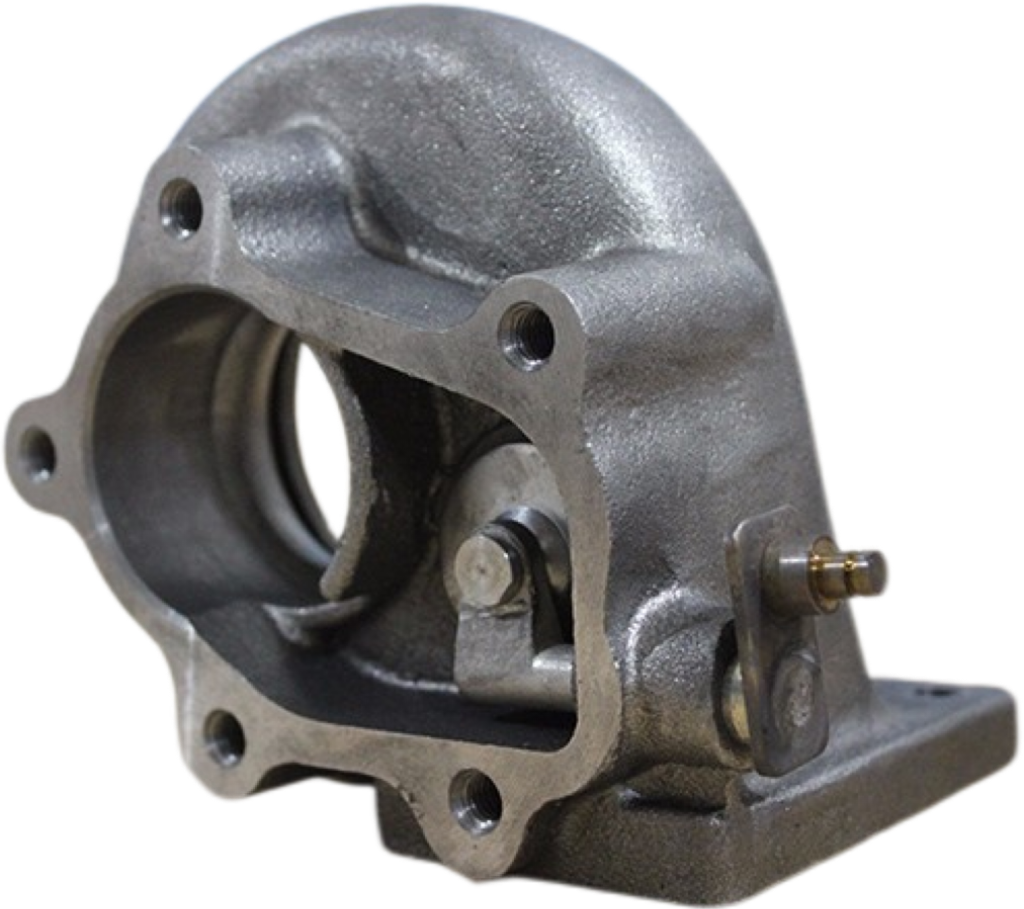

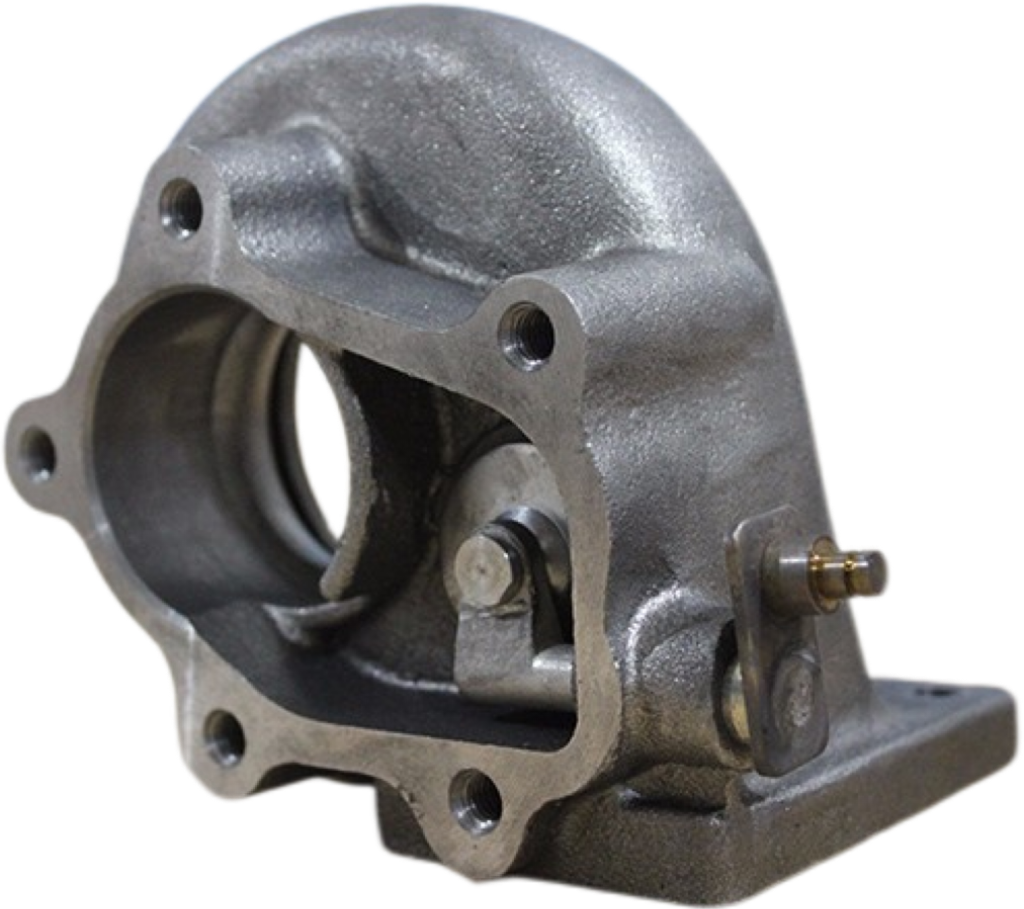

Introduction of turbocharger turbine housing:

Turbocharger turbine housing is a key component to improve engine power and efficiency. Turbocharger turbine housing can compress the intake air, increase the air density in the combustion chamber, and make the engine output stronger power. In this process, turbocharger turbine housing needs to withstand extreme high temperature and high pressure, so it has extremely high requirements for material durability, structural stability and processing accuracy. The cast iron housing we produce is sand casting, which makes it have excellent high temperature resistance, creep resistance and corrosion resistance. It is suitable for various types of passenger cars, commercial vehicles, construction machinery, heavy equipment, etc.

Advantages of turbo charger housing:

Turbo charger housing adopts heat treatment process to improve the mechanical properties and heat resistance of castings, so that it can withstand high temperature and high pressure for a long time.

Process flow:

1. Annealing treatment: Eliminate internal stress, improve the toughness of castings, and avoid deformation after long-term use.

2. Normalizing treatment: Improve the organizational structure of turbo charger housing, improve strength and wear resistance.

3. Quenching + tempering: Enhance high temperature resistance, so that the shell can still maintain a stable state under extreme conditions.

Technical specifications of turbine housing:

| Material of cast iron housing | Cast iron (alloy ratio can be adjusted according to demand) |

| Manufacturing process of turbo charger housing | Resin sand casting / lost foam casting |

| Surface treatment of turbo charger housing | Sandblasting / coating / galvanizing (according to customer requirements) |

| Applicable industries of turbine housing | Automobile, construction machinery, heavy equipment |

| Production capacity | Can be customized in batches, single piece or batch production |

| Delivery cycle | Depends on the order quantity, generally shipped within 15 days after payment |

FAQ:

1. Can you produce special shapes of cast iron housing?

Yes! We can make a variety of molds that can be customized according to your size, shape and material requirements.

2. What surface treatment options do you provide for cast iron housing?

Sandblasting, coating, galvanizing, oxidation treatment, etc. Can be provided according to customer needs to improve the corrosion resistance and aesthetics of turbo charger housing.

Our advantages:

1. Rich experience: We have more than 20 years of industry experience in the industry and have established long-term cooperative relationships with many international customers. In addition, turbine housing has been sold to germany, the united states, japan and other countries.

2. Flexible customization: Whether it is standard specifications or personalized customization, we can produce efficiently and deliver in a short time, so that your project progress is not affected.

3. Full service: From design, production follow-up to after-sales service, we maintain close communication throughout the process to help customers solve technical problems in the use of turbine housing, making procurement more worry-free.