Company Profile

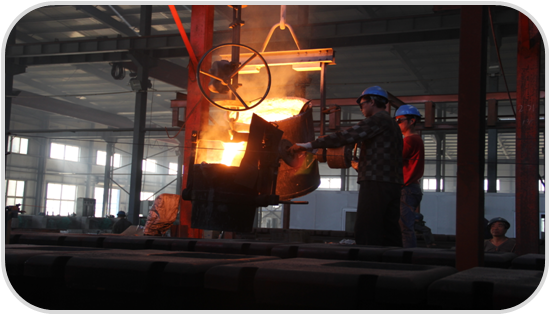

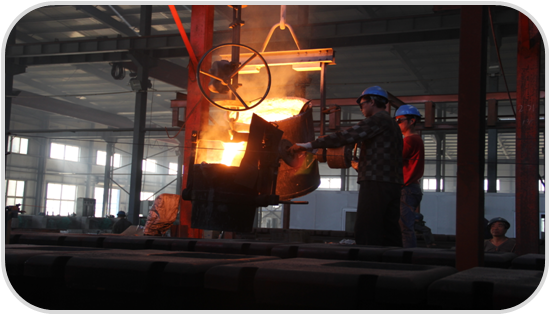

Dandong Hengrui Machinery specializes in supplying sand casting, precision casting, forging, machining and other kinds of metal parts, including valve parts, pump parts, laboratory equipment parts, electrical parts, automotive parts, railroad parts, marine parts, construction equipment parts, drainage parts, mining parts, as well as any shaped parts customized according to specific technical drawings or samples. We have an automated production line for sand castings (cast iron parts), advanced technology and first-class testing equipment to ensure high precision and stable quality, so that we can meet special requirements for all aspects of size, pressure, hardness, surface roughness and so on.

Material :cast iron

Workmanship : Sand casting

Surface treatment: On request

Application: Automotive, Engineering

China cast iron foundry valve body introduction:

Cast iron vent body is a key component in manufacturing valves. Cast iron vent bodies are usually made of cast iron. These cast iron valve parts play an important role in various industrial, construction and engineering applications. Cast iron valve parts are used to control the flow and pressure of fluids such as liquids, gases and steam. Cast iron valve parts are commonly used in piping systems, water supply systems, chemical plants, pharmaceutical plants and other applications.

Advantages of China cast iron cast iron valve body:

Cast iron is a robust and durable material suitable for a wide range of environments and can withstand high pressure and high temperature conditions, resulting in a long service life.

Cast iron plants remain stable under temperature and pressure fluctuations, ensuring valve reliability and consistency.

China cast iron valve bodies are produced by experienced foundries through precision workmanship and quality control to ensure reliability and performance.

| Product | Cast iron casting valve body |

| Processing | Sand Casting |

| Available Material | cast iron, stainless steel, copper, aluminum alloy etc. |

| More Processing | CNC Machining,Plastic Injection,Stamping,Die Casting,Welding,Forging, Mould Making,etc |

| Surface Finish | Powder Coating, Anodizing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Dacromet, Enamel Coating etc. |

| OEM | Available |

| Application | All kinds of cars,valve, pump, machinery,home appliance,electronic products,electric appliance,construction,computers,power switches,miniature switcher,architecture,hardware and plastic molds,sports equipment and gifts,and more. |

| Manufacturing Type | Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, Grinding, Stamping, Deep Drawing, CNC Punching, Laser Cutting, CNC Bending, Die Casting, Welding etc |

| Industries Served | Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical,Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS,STEP |

| QC | 100% Strict Inspection For Every Processing |

| One-stop Service | Custom Design, Fabrication, Assembly And Delivery |

Product Advantages

Internationally recognized quality: our factory's valve body parts have successfully entered the markets of many countries, and have won the trust and good reputation of customers all over the world by virtue of consistent and excellent quality, choosing us is choosing the international standard quality products.

Experienced: With more than 20 years of industry experience, we know all aspects of valve body fittings manufacturing very well, and can easily cope with both complex technical problems and special customized demands.

Rapid delivery: efficient production process and perfect supply chain management, to ensure short delivery time, so that your products quickly to the market, seize the first opportunity.

Considerate service: pre-sales provide professional technical advice to assist you in the selection; after-sales quick response to solve problems in use; after the warranty period is still continuous support, to eliminate your worries.

FAQ

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 20 years' experience for designing and producing casting parts and machining parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the mould cost and courier cost.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model, both available. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But if without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What's your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of cast.

For more information, please feel free to contact us!