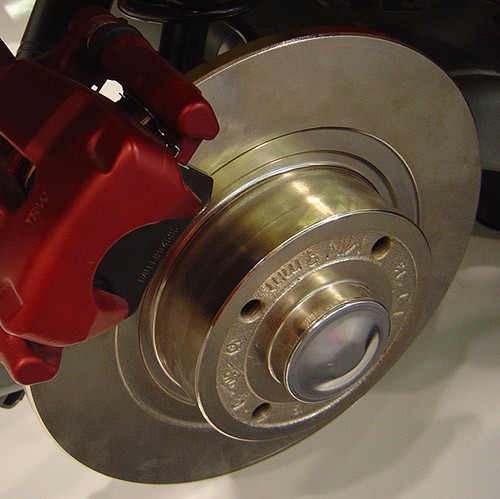

Introduction of automotive brake discs:

This automotive brake discs complies with my country's gray cast iron HT250 standard, and its performance is equivalent to the us G3000 standard, providing stable braking effect in various driving environments. Automotive brake discs have excellent strength and wear resistance, and are widely used in automobile braking systems, which can effectively improve braking efficiency and service life.

Advantages of disc brake rotor:

The core element ratio of disc brake rotor is strictly controlled. The carbon (C) content is 3.1~3.4% to ensure the good strength and toughness of the material; the silicon (Si) content is 1.9~2.3%, which enhances the oxidation resistance and high temperature resistance of cast iron; The manganese (Mn) content is 0.6~0.9%, which further improves the impact resistance of the material and keeps the disc brake rotor stable under high load. The above element content ratio is normal. If the customer has specific needs, we can also provide you with customized products.

CNC machining advantages:

1. CNC machining can ensure that the dimensional error of the disc brake is controlled within a very small range, and the surface flatness reaches an amazing degree.

2. CNC machining can continuously process the disc brake, shorten the production cycle, and improve production efficiency.

3. CNC machining of automotive brake discs adopts advanced processes and technologies, and the operation is more convenient and quick.

Packing and delivery of disc brake:

Wooden box/iron box, according to your requirements.

Port:

Dalian/Tianjin/Shenzhen/Shanghai, China.

Service and delivery of disc brake:

Support OEM and ODM customized services,

Standard export packaging (wooden box/iron box/pallet), support FOB, CIF and other transportation methods.

How to choose automotive brake discs?

Before replacing a brake disc, you must first check whether the replaced brake disc is a genuine part, the integrity of the product packaging, the anti-counterfeiting mark and whether the packaging mark is consistent with the mark on the brake disc, and whether the product model is consistent with the content of the certificate

About us:

Dandong Hengrui Machinery Co., Ltd. is a diversified enterprise that provides nearly a thousand casting and processing products, serving a wide range of industries. The company is equipped with three sets of advanced sand molding systems, which ensure the stability of casting quality. We have a dedicated mold inspection and maintenance workshop that can quickly respond to production needs and ensure the accuracy of product dimensions.