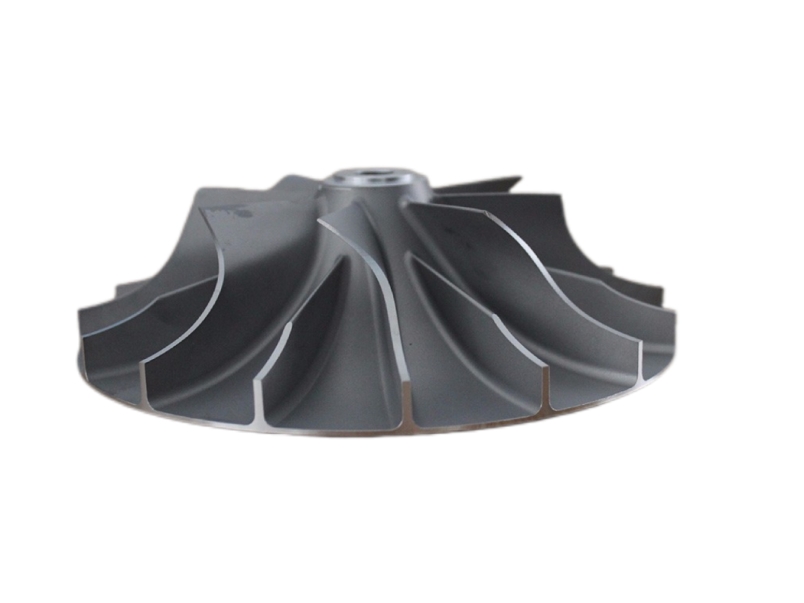

Introduction of turbo charger impeller:

Turbo charger impeller is a fluid mechanical component, widely used in compressor systems, and undertakes the key tasks of gas compression and boosting. Turbo charger impeller can be made of cast iron, stainless steel, copper, aluminum alloy and other materials, with excellent strength and corrosion resistance. During the manufacturing process, we use advanced five-axis CNC machining center for precision machining, so that the impeller surface finish can reach Ra0.8μm, thereby improving work efficiency and service life.

Advantages of turbine compressor impeller:

1. We have an experienced technical and service team, familiar with the needs of the international market, and can provide professional customized service solutions to tailor turbine compressor impeller for you.

2. Our factory is equipped with modern casting and CNC finishing equipment. Turbine compressor impeller can provide sand casting, precision machining and other processes for different application scenarios.

3. In addition to turbine compressor impeller, we can also provide turbocharger impellers, turbocharger housings, compressor housings, composite impellers, etc.

Quality inspection of turbine compressor impeller:

Non-destructive inspection:

1. Visual inspection of surface defects.

2. Dyeing penetrant test.

3. Radiographic test.

4. Ultrasonic test.

5. CMM size test.

Destructive inspection:

1. Tensile strength test.

2. Yield strength test.

3. Hardness test.

4. Spectroscopic chemical composition test.

FAQ:

1. Can you provide customized services?

Yes, we can carry out OEM customized production according to the drawings or samples provided by customers.

2. How long is the delivery cycle of turbo charger impeller?

The specific delivery time depends on the order quantity and customization requirements. Generally, it is 2-4 weeks. We will arrange production as soon as possible after confirming the order.

3. How to ensure the quality of turbo charger impeller?

Our production process strictly implements the quality management system and conducts comprehensive inspections in the factory, including non-destructive and destructive tests.

About us:

In terms of technology, we have introduced and adopted advanced casting technologies such as high-pressure injection molding, shell core making, and three-dimensional process design. In terms of casting equipment, we first introduced two detachable box-type FBOⅢ injection molding automatic production lines from Japan (box size: 605×505×200㎜), which can produce 120 sand molds per hour and 7,000 tons of castings per year. Later, we introduced a world-leading static pressure automatic production line (box size: 1000×800×350/300㎜), which can produce 90 sand molds per hour and 30,000 tons of castings per year, and the production scope has been broadened.