Stainless Steel Casting

We can provide a variety of stainless steel casting services for many industries, such as construction machinery, automotive or other large equipment sectors. We provide stainless steel investment casting and stainless steel sand casting processes that allow you to flexibly cast stainless steel parts for various requirements.Our stainless steel castings usually use the investment precision casting process. Investment precision casting is a casting process with little or no cutting. It is suitable for casting of various types and alloys and can produce castings with high size precision and good surface quality.

Common Material of Stainless Steel Casting

| Alloy name | Performance | Material properties | application industry |

| 304L stainless steel | Tensile Strength: 485-655 MPa, Hardness: 70-88 HRB | Ductility (lower carbon for weldability) | Chemical, Oil and Gas |

| 316 stainless steel | Tensile Strength: 515-690 MPa, Hardness: 75-95 HRB | Excellent Corrosion Resistance (with molybdenum) | Paper industry, Chemical processing equipment, Pharmerceutical |

| 316L stainless steel | Tensile Strength: 485-655 MPa, Hardness: 75-95 HRB | Improved Weldability, Corrosion Resistance | Marine, Chemical |

| 201 stainless steel | Tensile Strength: 620-795 MPa, Hardness: 70-88 HRB | Cost-Effective (lower nickel), Corrosion Resist. | Construction, Automotive |

| 2205 stainless steel | Tensile Strength: 620-800 MPa, Hardness: 20-35 HRC | Resistance to Stress and Corrosion, Used for Welding | Oil & Gas, Chemical |

Stainless Steel Casting Surface Treatment Process:

1

Polishing treatment

Mechanical polishing and electrolytic polishing are used. Mechanical polishing uses mechanical equipment to smooth the surface, while electrolytic polishing uses electrolyte and current to remove surface oxides and improve smoothness.

2

Sand blasting

By blasting sand or abrasive at high speed to the surface, it removes oxides and dirt, increases surface roughness, and improves touch and aesthetics.

3

Electroplating treatment

Plating a metal or alloy on the surface of stainless steel to change its surface characteristics and enhance wear resistance and corrosion resistance.

4

Anti-fingerprint treatment

Reduce fingerprint traces through special coating and keep the surface clean and beautiful.

5

Etching and wiredrawing

Etching engrave patterns or words through chemical or physical methods, while wiredrawing forms texture through mechanical friction. Both can provide personalized decorative effects.

6

Pickling passivation

Pickling removes surface oxides and rust, and passivation forms a protective film to improve corrosion resistance.

Advantages of Stainless Steel Investment Casting

1. High size accuracy and low surface roughness.

2. Compared to other casting processes, the allowed part complexity is high.

3. Good appearance quality, low surface roughness, and sometimes even the secondary machining or surface treatment process can be omitted.

4. Stainless steel investment casting is suitable for casting of various types and alloys, such as small blades for jet engines and streamlined outline parts.

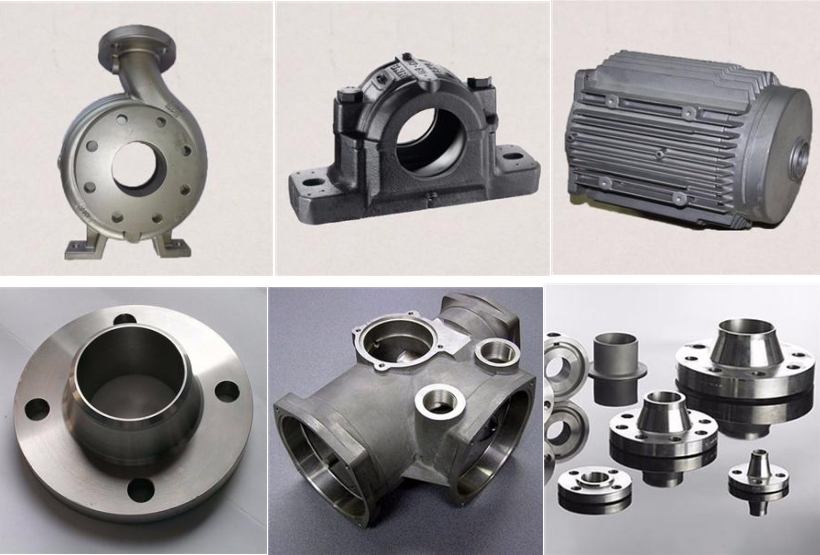

Sample Display