Sand Casting:

A casting method that produces castings in sand molds. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. We not only have a dedicated sand casting factory workshop, but also use automated production, so our Dandong Hengrui Machinery Co., Ltd has a strong production supply capacity. In addition, we can also provide you with customized services according to the drawings you provide.

Sand Casting Advantages:

1

Strong applicability

Suitable for castings of various sizes and shapes, as well as blanks with complex internal cavities.

2

Low cost

Sand casting molds are low cost and the molds can be reused, making them cost-effective for part production.

3

Short manufacturing cycle

Compared with other casting methods, sand casting has a relatively short manufacturing cycle and short delivery time.

4

Versatility

Sand casting can be used for a variety of materials, including high melting point metals such as various steels, ductile iron, and gray cast iron.

5

Environmental friendly

Sand casting recycles waste materials, has a lower ecological footprint than most other casting methods and is more environmentally friendly.

6

Widely used

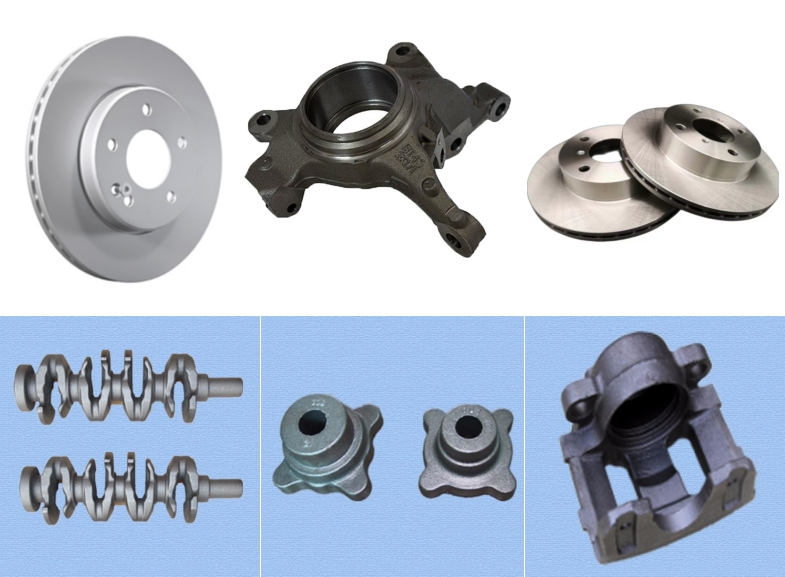

It is often used in the manufacture of large engine parts, industrial machinery parts, etc. Such as automobile brake discs, crankshafts and other castings.

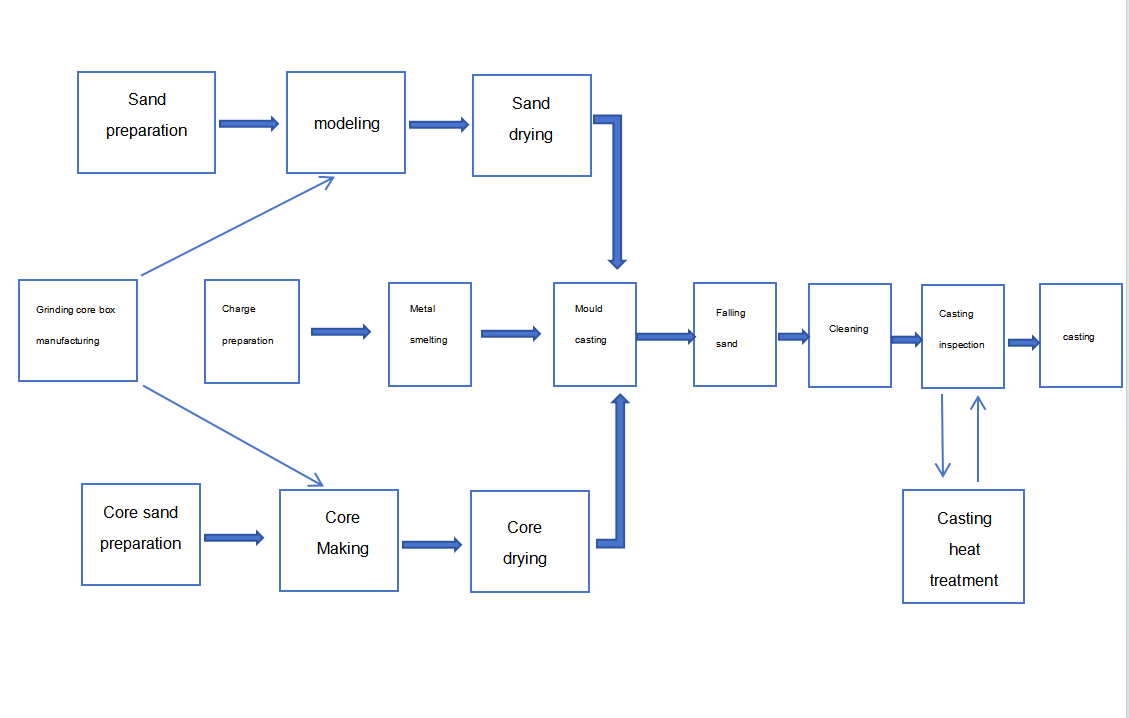

Sand Casting Process:

Sand Casting Parts Samples:

Why Choose Us?

1. We have a complete production line, advanced technology and first-class testing equipment to ensure the high precision and high quality of the products.

2. We have advanced technology and first-class testing equipment.

3. We specialize in supplying various metal parts with processes such as sand casting, precision casting, forging and machining.