Investment Casting :

Investment casting, also known as "lost wax casting", is a metal forming process. The basic principle is to use fusible materials (such as wax) to make a mold for the part, then coat the mold surface with multiple layers of refractory materials, and form a shell after drying and hardening. The mold material is melted by heating to form a cavity shell, and finally the metal liquid is injected into the shell and cooled to form.

Investment casting has the following features and advantages:

It can produce castings with complex shapes and high precision using a variety of metal materials (such as aluminum alloys, copper alloys, stainless steel, etc.). Since the wax pattern can produce very fine details, castings with complex features and high dimensional accuracy can be manufactured. In addition, this casting process can achieve small batch production, providing great flexibility for manufacturing castings with specific or special requirements.

Investment Casting Process Steps:

1

Wax patterning

The wax is pressed into the mold cavity and cooled to form a wax pattern. Accuracy in this step is very important because changes in the wax pattern will affect the final dimensions and tolerances of the investment casting part.

2

Making wax trees

Welding multiple wax models to a casting system to form a tree-like structure allows efficient casting of multiple parts at the same time. This process requires careful handling to ensure that the wax models are firmly bonded.

3

Shell making:

The shell making process involves repeatedly dipping the wax tree into a ceramic slurry and coating it with refractory sand. This creates a ceramic shell around the wax pattern. This shell will later serve as a mold for the metal casting.

4

Dewaxing and Firing

The shells are baked at high temperatures to remove any wax residue and strengthen the mold for the pouring stage. Proper control of temperature and time is crucial in this step to guarantee the stability and strength of the shell.

5

Melting and Pouring

After the ceramic shell is prepared, the molten metal is poured into the fired mold and cooled to form. The temperature and pouring speed must be strictly controlled during the process to achieve uniformity and prevent defects.

6

Heat treatment

After the casting has cooled, the individual components are separated from the wax tree. In addition, techniques such as normalizing, quenching and tempering are used to adjust the hardness and mechanical properties of the final product.

Applicable Materials

The materials applicable to investment casting include a variety of metals and non-metallic materials. The following are several common applicable materials and their characteristics:

1. Stainless steel and carbon steel: These two materials are widely used in investment casting and can meet the requirements of high precision and high strength. Stainless steel and carbon steel castings have smooth surfaces and uniform density.

2. Alloys: Such as ferritic stainless steel, chromium-nickel alloy, tin-based alloy and tungsten-molybdenum alloy. Alloy materials have higher strength and corrosion resistance and are suitable for applications requiring high-precision castings.

3. Copper: It is often used to make molds, sculptures, handicrafts and other products with high artistic and precision requirements. Copper materials have good fluidity under high heat conditions, and adding a small amount of other metal elements can increase its hardness and strength.

4. Aluminum: It is also widely used in investment casting, mainly in the automotive and aviation industries. Aluminum materials have excellent thermal conductivity and corrosion resistance, and the surface of the castings is flat and pore-free, which is suitable for high-temperature resistant and high-strength parts.

Investment Casting Parts Samples

Why Choose Us?

1. Strong production capacity:

We have independent factories, each production process has an independent production workshop, and is equipped with advanced high-end equipment. Our team of engineers has successfully produced products for international companies in different industries.

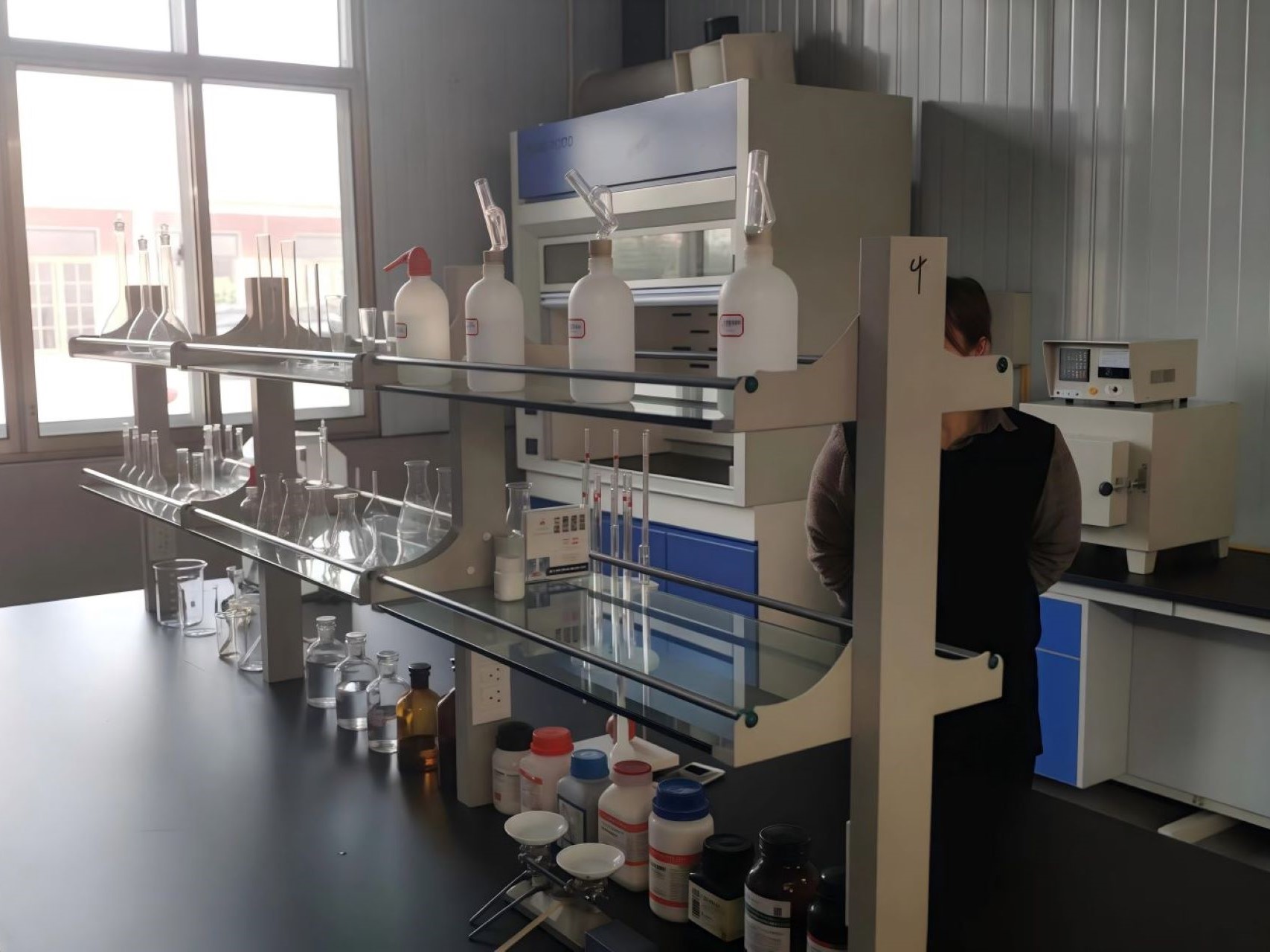

2. Strict quality control:

We have a professional quality control team, from pre-production evaluation to strict control during the production process, to various tests of finished products, requiring each product to meet customer needs.

3. Wide range of applications:

Our investment casting products are widely used in oil pipelines, automobiles and railways, agricultural machinery, construction machinery, shipbuilding and other fields. If you have any questions about whether investment casting is suitable for your project, our professional team will provide you with customized high-quality solutions to help your business succeed.